What is Aluminum Picket Railing?

Aluminum picket railing is a modern interpretation of classic baluster design, using extruded aluminum components to create a durable, maintenance-free alternative to traditional wood or wrought iron railings. The system consists of aluminum posts anchored to your deck or porch structure, horizontal top and bottom rails that connect these posts, and vertical pickets (also called balusters or spindles) that fill the space between rails to create a safe barrier.

Unlike wood railings that require annual staining and sealing, or steel railings that rust and need painting, aluminum picket systems are engineered to withstand Canadian weather conditions with virtually no maintenance for decades. The aluminum is powder-coated in factory-controlled conditions, creating a finish that's far more durable than field-applied paint or stain. This coating is UV-resistant, won't fade in intense sunlight, and creates a barrier against moisture that prevents corrosion even in coastal environments where salt spray would destroy traditional materials.

The design versatility of aluminum picket railing makes it suitable for virtually any architectural style. Traditional homes benefit from narrow picket designs that echo historical baluster patterns, while contemporary properties can embrace wider, more minimalist spacing. The ability to choose from dozens of powder-coat colors means your railing can complement your home's exterior perfectly, whether you prefer classic white, modern black, natural bronze tones, or custom colors matched to your specific requirements.

Aluminum picket railing has become the standard choice for residential decks across Canada, particularly for families with children or pets where the solid barrier of vertical pickets provides peace of mind that glass systems cannot match. The tactile quality of aluminum rails provides a comfortable handhold for navigating stairs, and the robust construction can withstand years of daily use, leaning, and the occasional impact from outdoor furniture or recreational equipment without sustaining damage.

Key Benefits of Aluminum Picket Systems

Zero Maintenance Requirements

The most compelling advantage of aluminum picket railing is the elimination of maintenance that consumes weekends with traditional wood systems. Wood railings require annual or biannual sanding, staining, and sealing to prevent water infiltration, rot, and UV damage. This maintenance cycle is not optional – neglecting it for even a single season can lead to accelerated deterioration, splinters, and eventual structural failure. A typical wood railing might consume 20-30 hours of labor per year in maintenance, along with hundreds of dollars in staining products.

Aluminum railing eliminates this burden entirely. The powder-coated finish is baked onto the aluminum in controlled factory conditions at temperatures exceeding 400 degrees Fahrenheit, creating a molecular bond that's far superior to any paint or stain that can be applied in the field. This finish is engineered to resist UV degradation, temperature cycling, moisture penetration, and chemical exposure. In practical terms, this means your railing will look virtually identical in year twenty as it did on installation day, with nothing more than an occasional rinse with a garden hose to remove pollen or dirt.

The corrosion resistance of aluminum is another maintenance advantage. While steel or wrought iron railings will develop rust within years (or months in coastal areas), aluminum develops a thin, stable oxide layer that actually protects the underlying metal from further oxidation. Even in the harsh salt-spray environment of oceanfront properties, powder-coated aluminum railings remain structurally sound and visually pristine. This makes aluminum the only practical choice for cottages, beach houses, or any property where salt exposure would destroy traditional materials.

Superior Durability and Lifespan

Aluminum picket railing systems are engineered for multi-generational lifespan. Where wood railings might last 10-15 years before requiring replacement (or less if maintenance is neglected), quality aluminum railing systems are commonly warranted for 20-30 years and regularly exceed 50 years of service life. The structural integrity of aluminum doesn't degrade with weather exposure – the material doesn't rot, split, warp, or become brittle with age.

The extruded aluminum components used in quality railing systems have wall thicknesses and alloy compositions specifically engineered for railing applications. This isn't the thin, flexible aluminum you might find in budget-grade products or DIY kits. Professional-grade systems use 6000-series aluminum alloys with sufficient wall thickness to resist bending, maintain rail height under snow loads, and handle the lateral forces from people leaning or children playing without flexing or loosening over time.

Impact resistance is another durability consideration where aluminum excels. Wood railings can split or crack from impacts with furniture, grills, or recreational equipment. Aluminum has natural flexibility that allows it to absorb impacts and return to shape without permanent deformation or damage. For families with active children, dogs, or frequent entertainment where furniture gets moved regularly, this resilience prevents the need for constant repairs that plague wood railing systems.

Child and Pet Safety Features

Safety is a primary consideration in railing design, and aluminum picket systems offer specific advantages for families with young children or pets. The solid barrier created by vertical pickets provides a physical barrier that's more reassuring than glass panels for parents concerned about falls. Children cannot climb picket railings the way they can scaled cable or horizontal rail systems, and the picket spacing can be precisely controlled to meet code requirements for preventing small heads or bodies from passing through.

Canadian building codes typically require picket spacing of four inches or less – a measurement specifically designed to prevent infant heads from fitting through the gap. Quality aluminum railing manufacturers design their systems with precise spacing that meets or exceeds these requirements, with no possibility of spacing widening over time as can happen with wood systems where pickets can loosen or shift. The smooth powder-coated finish also eliminates the splinter hazards that make wood railings dangerous for small hands exploring their environment.

For pet owners, aluminum picket railing provides containment without the maintenance burden of wood. Dogs cannot chew aluminum rails, cats cannot claw the powder-coated finish, and the structure won't weaken over time from animal interaction. For homes with small dogs or puppies, the narrow picket spacing prevents escape while providing visibility that helps nervous pets acclimate to elevated decks. The solid construction also means pets can lean against the railing without risk of panels flexing or gaps opening.

Environmental Considerations

Aluminum is one of the most recyclable materials on earth, with over 75% of all aluminum ever produced still in use today. When an aluminum railing eventually reaches end of life (typically after 50+ years), it can be recycled indefinitely without loss of material properties. This contrasts sharply with pressure-treated wood that becomes hazardous waste due to chemical treatments, or vinyl systems that release toxins during manufacturing and disposal.

The manufacturing energy for aluminum has decreased dramatically in recent decades, and much of the aluminum in modern railing systems contains significant recycled content. This makes aluminum picket railing one of the most environmentally responsible choices available. Additionally, the elimination of annual staining means no volatile organic compounds (VOCs) from stains and sealers leaching into your soil and groundwater each year – a consideration for homeowners near wells, ponds, or natural areas.

🛡️ Zero Maintenance

No staining, painting, or sealing ever. Factory powder-coat finish lasts 50+ years without fading or peeling.

👶 Child Safe Design

Code-compliant spacing prevents climbing. Smooth finish eliminates splinters. Non-toxic materials.

⚡ Weather Resistant

Won't rot, rust, warp, or crack. Engineered for Canadian winters and coastal salt spray.

♻️ Sustainable Choice

Infinitely recyclable aluminum. No toxic treatments. No annual VOC emissions from staining.

Design Styles and Configurations

Traditional Narrow Picket

Traditional narrow picket designs feature round or square balusters approximately 5/8" to 3/4" in diameter, spaced at regular intervals to create the classic baluster appearance found in heritage homes and traditional architecture. This style typically uses spacing in the 3.5" to 4" range, maximizing the number of pickets for a refined, formal appearance that echoes historical wrought iron or turned wood balusters.

Narrow picket systems are ideal for Colonial, Victorian, Craftsman, and other traditional architectural styles where the railing should complement rather than compete with the home's design vocabulary. The narrow profile creates vertical rhythm and visual interest without appearing heavy or industrial. For historic districts or homes with strict architectural guidelines, narrow picket aluminum railing can replicate the appearance of original wood or iron railings while providing modern performance and eliminating maintenance.

The narrow diameter also makes these systems appear lighter and less obtrusive, an advantage for second-story balconies or front porches where you want safety and code compliance without creating a cage-like appearance. The shadow lines created by numerous narrow pickets add depth and dimension to your deck, creating visual interest that wider picket systems cannot match.

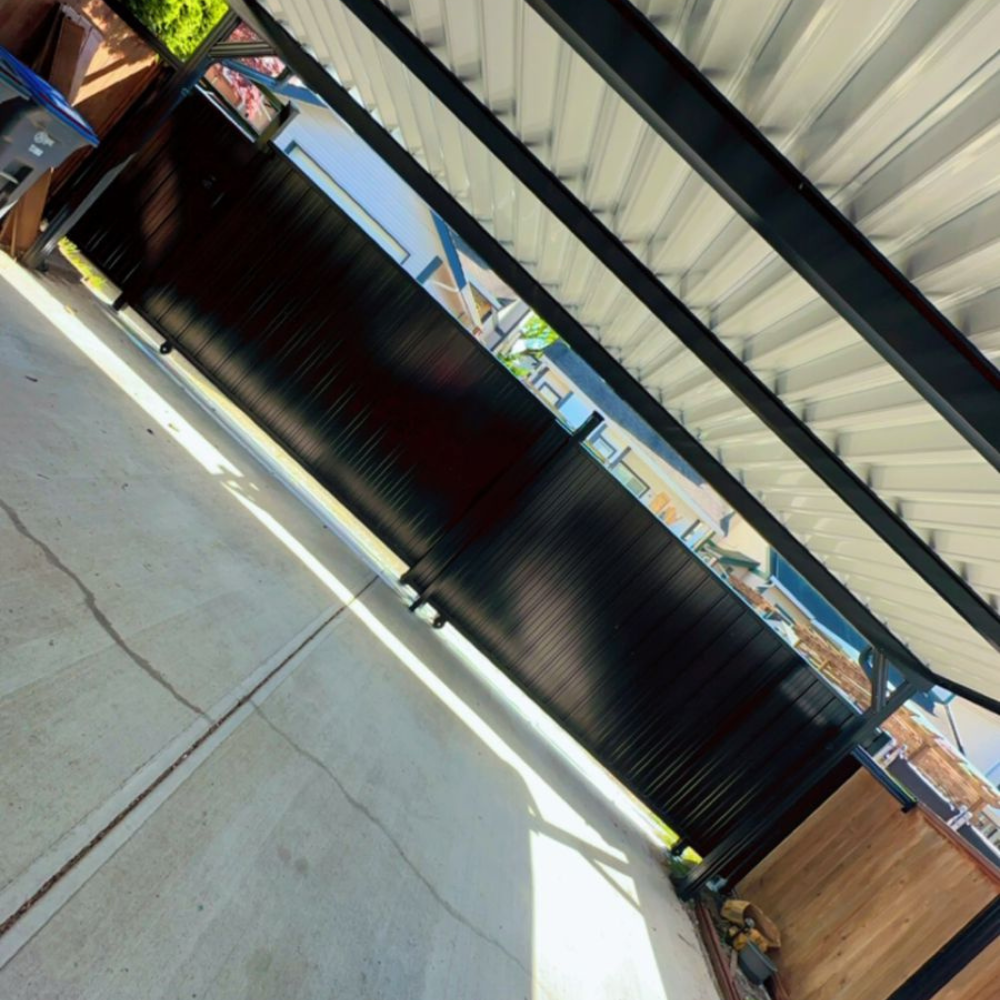

Contemporary Wide Picket

Wide picket designs embrace a more modern aesthetic with larger diameter balusters, typically 1.25" to 2" wide, spaced farther apart while still meeting code requirements. This creates a cleaner, more minimalist appearance that complements contemporary and modern architecture. The wider spacing (while still maintaining safe 4" gaps) reduces visual complexity and creates a more open feeling, allowing more light to pass through to lower decks or ground-level areas.

Contemporary designs often incorporate square or rectangular picket profiles rather than traditional round balusters. These geometric shapes create sharp shadow lines and emphasize horizontal lines when used with matching square rails. For modern homes with horizontal siding, flat roofs, or geometric facades, wide square picket railing creates visual harmony and reinforces the architectural language.

The reduced number of pickets in wide-spacing designs also offers a subtle cost advantage, as fewer components are required to fill the same linear footage. However, the primary motivation for choosing wide picket systems is aesthetic – the clean, uncluttered appearance that defines modern design sensibility. This style pairs exceptionally well with composite decking, horizontal cable rail accents, or minimalist outdoor furniture.

Mixed Material Designs

Advanced railing designs often incorporate aluminum pickets with other materials to create unique visual effects. One popular approach combines aluminum pickets in the upper portion of the railing with horizontal cable or glass panels in the lower section, providing safety without completely blocking ground-level views. This is particularly effective for elevated decks where you want to maintain sightlines to landscaping, water features, or children playing below.

Another mixed material approach uses aluminum posts and rails with decorative metal panels insert instead of traditional pickets. These panels can feature laser-cut patterns, geometric designs, or organic motifs that transform functional railing into artistic elements. This approach is popular for front entry stairs, courtyard railings, or any location where the railing is a prominent visual feature rather than purely functional.

For homeowners who want the airiness of cable rail with the child-safety of pickets, hybrid systems place vertical aluminum pickets at child-accessible levels (roughly 24" from deck surface and below) with horizontal cables in the upper portion. This provides the safety barrier where needed while maintaining maximum visibility for adults. The combination also prevents the "horizontal ladder" concern with full cable rail systems that children might be tempted to climb.

Traditional Narrow

Classic appearance, maximum pickets, refined look for heritage homes

Modern Wide

Contemporary spacing, clean lines, minimalist aesthetic

Square Profile

Geometric design, sharp shadows, modern architecture

Safety Standards and Code Compliance

Canadian Building Code Requirements

The National Building Code of Canada establishes minimum safety standards for guard railings, which provinces and municipalities then adopt or modify with local amendments. Understanding these requirements is essential because non-compliant railings can result in failed building inspections, insurance complications, and liability concerns if accidents occur.

The fundamental requirement is that guards (railings) must be installed on elevated walking surfaces more than 24 inches above grade. The minimum height for residential guards is 36 inches, measured vertically from the deck surface to the top of the rail. For stairs, the handrail must be between 32 and 38 inches above the nosing (front edge) of the treads. These measurements are non-negotiable – even a railing that's half an inch too short can fail inspection.

The structural load requirements are equally important. Guards must withstand a concentrated horizontal load of 0.5 kN (approximately 112 pounds) applied at any point along the top rail without failing or deflecting excessively. This load is intended to simulate someone falling against or grabbing the railing, and it's tested at the weakest point in the system – typically the center span between posts. Quality aluminum railing systems are engineered with post spacing and rail dimensions that meet or exceed these loads with significant safety margin.

Picket Spacing and Infill Requirements

The most critical safety specification for picket railing systems is the maximum opening size, designed to prevent small children from falling through or getting their heads trapped. Canadian building code limits openings to 100mm (approximately 4 inches) measured between adjacent pickets. This dimension is carefully calculated to prevent a small child's head from passing through while still allowing for reasonable air flow and visibility.

This measurement must be maintained throughout the entire railing system, not just at one point. The spacing is measured as the smallest clear dimension, meaning diagonal measurements count if pickets are slightly misaligned. Quality aluminum railing systems achieve consistent spacing through precise manufacturing tolerances and installation systems that lock pickets in position. This is a significant advantage over field-assembled wood railings where spacing can vary and potentially widen as wood shrinks or fasteners loosen.

For stairs, additional requirements apply. The triangular space formed by the stair tread, riser, and bottom rail cannot exceed the 100mm opening limit. This often requires a different picket configuration or closer spacing on stair sections. Professional installers understand these nuances and design stair railings that meet code while matching the aesthetic of the main deck railing.

Load Testing and Engineering

Professional-grade aluminum railing systems undergo extensive engineering analysis and physical load testing to verify code compliance. Manufacturers test systems under loads exceeding code minimums to establish safety factors and determine maximum post spacing for various configurations. This engineering data is typically available in published load tables that specify allowable spans based on post size, rail dimensions, and mounting method.

For residential applications, this engineering is typically generic – the manufacturer has tested standard configurations and provides installation instructions that ensure code compliance when followed correctly. However, for unique applications like curved railings, extra-tall rails, or installations in high wind areas, custom engineering may be required. Professional installers can obtain project-specific engineering stamps when local building departments require them, though this is more common in commercial applications.

The post-to-structure connection is the most critical component from a structural perspective. Posts must be anchored to solid framing capable of resisting the lateral loads imposed on the railing. This typically means mounting to rim joists, blocking, or concrete surfaces – never just to deck boards. Surface-mount posts use heavy-duty brackets with multiple fasteners, while through-bolt mounting provides even higher strength by passing bolts completely through the deck framing.

Code Compliance Guarantee

Professional aluminum railing installers guarantee code compliance for your installation. We work with local building inspectors to ensure every detail meets current requirements, providing documentation and engineering data when required. Our installations pass inspection on the first attempt, preventing delays and costly modifications.

Color Options and Finishes

Standard Powder-Coat Colors

Most aluminum railing manufacturers offer a core selection of powder-coat colors designed to complement popular exterior finishes and architectural styles. These standard colors are typically available at base pricing and include variations of white, black, bronze, and beige tones that account for approximately 80% of residential railing installations.

White and Off-White: Classic white railing remains the most popular choice, particularly for traditional homes with white or light-colored siding. Pure white provides maximum contrast against dark decking and creates the clean, crisp appearance associated with coastal and colonial architecture. Off-white or cream variations offer a softer look that coordinates with beige or tan siding without the stark contrast of pure white. These light colors also remain cooler to the touch in direct sunlight, an important consideration for handrails in sunny locations.

Black and Charcoal: Black aluminum railing has surged in popularity with modern and contemporary architecture. Matte black creates a sophisticated, high-end appearance that complements metal accents, dark window frames, and industrial-inspired design elements. The dark color also makes the railing visually recede, creating an more open feeling than white railing while still providing a solid safety barrier. Charcoal gray offers a softer alternative that's less stark than pure black while maintaining the modern aesthetic.

Bronze and Copper Tones: Bronze aluminum railing provides a warm, natural appearance that complements brick, stone, and earth-toned siding. Oil-rubbed bronze finishes create a traditional look with subtle color variation that adds visual interest, while lighter bronze tones work well with natural wood decking. Copper-toned finishes are less common but can create stunning effects that coordinate with copper roof accents or architectural details.

Custom Color Matching

For homeowners seeking perfect coordination with specific exterior colors, most manufacturers offer custom color matching services. This involves matching the powder-coat finish to a specific paint sample, typically identified by manufacturer color codes from Benjamin Moore, Sherwin-Williams, or other major paint brands. Custom colors allow your railing to disappear against matching siding, blend with trim colors, or create intentional contrast with specific design elements.

The custom color process typically adds 2-3 weeks to production time and carries premium pricing, but the result is a truly cohesive exterior appearance. This is particularly valuable for homes with unusual color schemes, historic color preservation requirements, or distinctive architectural styles where standard colors would clash. Some manufacturers require minimum order quantities for custom colors, making this option more practical for larger installations or projects with multiple homes using the same custom finish.

Textured and Special Finishes

Beyond color selection, the texture of the powder-coat finish affects both appearance and performance. Most standard powder-coats have a slight texture that helps hide minor imperfections and provides a non-slip surface on handrails. Smooth glossy finishes are available but show fingerprints and scratches more readily, making them less popular for railing applications.

Some manufacturers offer enhanced finishes with specific performance characteristics. Sand-textured finishes provide additional grip on handrails and stairs, valuable for regions with frequent rain or for homeowners with mobility concerns. Metallic powder-coats incorporate fine metal flakes that create subtle shimmer and depth, adding visual interest while maintaining durability. These specialty finishes typically carry premium pricing but can create distinctive effects worth the investment for prominent installations.

| Color Family | Best For | Heat Retention | Maintenance |

|---|---|---|---|

| White/Cream | Traditional homes, coastal style | Low (Cool) | Shows dirt more readily |

| Black/Charcoal | Modern homes, industrial style | High (Hot) | Hides dirt well |

| Bronze/Copper | Natural settings, brick homes | Medium | Minimal visible dirt |

| Beige/Tan | Earth tones, stucco homes | Low-Medium | Very forgiving |

| Custom Colors | Perfect matching, unique homes | Varies by color | Depends on shade |

Professional Installation Process

Pre-Installation Planning

Professional aluminum railing installation begins with detailed site measurement and planning. Unlike simple material delivery for DIY projects, professional installation includes comprehensive assessment of your deck structure, identification of obstacles like lights or gas lines, discussion of design preferences, and creation of detailed installation plans that account for every corner, stair, and gate location.

The installer will evaluate your deck's structural capacity to support railing loads. Older decks may require reinforcement of rim joists or addition of blocking to provide adequate anchoring points for posts. This assessment prevents future problems with loose posts or failed connections that compromise safety. For ground-level installations into concrete patios or walkways, the installer will verify adequate concrete thickness and condition to accept anchor bolts.

Design consultation is another critical pre-installation step. The installer will help you select appropriate styles, colors, and configurations that meet your aesthetic goals while ensuring code compliance and structural adequacy. This includes decisions about post cap styles, which can be flat, pyramid-shaped, or decorative ball caps; whether to incorporate lights in post caps for evening ambiance; and how to handle transitions between different railing sections or changes in deck elevation.

Post Installation and Positioning

Post installation is the foundation of any railing system, both literally and figuratively. Posts must be positioned precisely to maintain proper spacing (typically 4 to 6 feet depending on system design), plumb in both directions, and securely anchored to structural framing. The method of attachment depends on deck construction and accessibility.

For surface-mount installations on top of deck boards, heavy-duty brackets bolt or screw through the deck boards into the rim joist below. Quality brackets use 4-6 fasteners and distribute loads across a large footprint to prevent pull-through or tearing. The base plate of the post mounting system typically includes a rubber gasket to prevent water infiltration at the penetration point, protecting the underlying structure from moisture damage.

Through-bolt mounting provides superior strength by passing bolts completely through the deck framing and securing with washers and nuts on the opposite side. This method requires access beneath the deck and is typically used on new construction or decks with accessible joists. The resulting connection is extremely rigid and unlikely to loosen over time. For concrete installations, expansion anchors or adhesive anchors secure post bases directly to the concrete surface.

Rail and Picket Assembly

Once posts are installed and verified for proper spacing and plumb, the rail assembly process begins. Top and bottom rails are cut to precise lengths to span between posts, with mitered corners for direction changes and special fittings for stair transitions. Most aluminum railing systems use hidden fastener designs where screws are accessed from the underside of rails or concealed by decorative covers, creating a clean finished appearance.

Pickets are inserted into channels in the top and bottom rails, with spacing maintained by built-in stops or separate spacer components that lock pickets at precise intervals. This factory-engineered spacing ensures code compliance throughout the system without requiring individual measurement of each gap. The pickets may be pre-cut to length or trimmed on-site to account for slight variations in deck height or stair angles.

Stair railings require special attention to angle, height, and picket spacing. The handrail must maintain proper height above each tread nose while transitioning smoothly from the deck-level railing. This typically involves angled rail sections and custom-cut pickets to maintain consistent spacing on the sloped surface. Professional installers use jigs and angle-finding tools to ensure accurate cuts and consistent appearance.

Final Details and Inspection

Installation concludes with attachment of post caps, installation of any integrated lighting, final tightening of all connections, and thorough cleaning to remove installation debris and fingerprints. The installer will verify that all gates operate smoothly, latches engage properly, and any electrical connections for post lights function correctly.

Professional installers coordinate building inspection if required by local code. They'll point out key safety features to the inspector, provide manufacturer documentation of load ratings and code compliance, and address any concerns raised during inspection. Having professional installation typically ensures first-time inspection approval, avoiding delays and costly modifications that can result from failed DIY installations.

Professional Installation Benefits

Warranty Protection: Most manufacturers require professional installation to honor product warranties. DIY installation may void coverage for material defects.

Code Compliance: Professional installers guarantee code compliance and work with building inspectors to ensure approval.

Structural Integrity: Proper anchoring and load distribution prevent future failures and safety hazards.

Time Savings: Professional teams complete installations in days that might take homeowners weeks.

Maintenance and Long-Term Care

Routine Cleaning

The beauty of aluminum picket railing is that maintenance is limited to occasional cleaning rather than the intensive annual treatment required for wood. For most installations, cleaning the railing 2-3 times per year is sufficient to maintain appearance and remove accumulated dirt, pollen, or environmental contaminants.

Basic cleaning involves rinsing the railing with a garden hose to remove loose dirt and dust. For more thorough cleaning, mix mild dish soap with warm water and apply with a soft cloth or sponge. Work from top to bottom, cleaning a section at a time, then rinse thoroughly with clean water. Avoid abrasive cleaners, steel wool, or harsh chemicals that can damage the powder-coat finish. Most household cleaners are safe for powder-coated aluminum, but test in an inconspicuous area first if uncertain.

For stubborn stains or oxidation, specialized aluminum cleaning products are available at hardware stores. These cleaners use mild acids or chelating agents to remove mineral deposits, rust stains from sprinkler overspray, or other discoloration without harming the finish. After cleaning, some homeowners apply automotive wax to create an additional protective layer and make future cleaning easier, though this is optional rather than necessary for protection.

Seasonal Considerations

In regions with harsh winters, minimal seasonal maintenance can extend the appearance life of your railing. Before winter, remove any accumulated leaves or debris from rail channels and post caps where water might collect and freeze. Ice formation in these areas can crack powder-coat finishes or trap moisture against the aluminum. A quick clearing of debris prevents these issues.

After winter, inspect for any damage from ice, snow removal equipment, or furniture movement. Look for scratches in the powder-coat that expose bare aluminum, loose post caps, or any fasteners that may have worked loose during freeze-thaw cycles. Minor powder-coat damage can be touched up with matching paint pens available from the manufacturer, though bare aluminum develops a protective oxide layer naturally and won't corrode like steel.

In coastal areas, more frequent cleaning helps prevent salt buildup that can dull the finish over time. While aluminum won't rust from salt exposure, accumulated salt residue can create a hazy appearance if not rinsed away periodically. A monthly rinse during salt spray season keeps the railing looking pristine and prevents long-term dulling of the finish.

Hardware Inspection and Adjustment

Once annually, inspect all fasteners and connections for tightness. Pay particular attention to post mounting brackets, gate hinges, and latch mechanisms that experience regular movement and stress. Tighten any loose screws or bolts using appropriate tools, being careful not to overtighten and strip threads. Most aluminum railing fasteners are stainless steel to prevent corrosion, but occasionally you may need to replace a rusted screw if lower-grade hardware was used initially.

Gate hardware requires the most attention. Hinges should be checked for smooth operation and lubricated if squeaky. Self-closing gate mechanisms (required for pool fencing) should be tested to ensure they consistently close and latch properly. Spring tension may need adjustment as components wear or settle. Latches should engage fully without excessive force, and magnetic catches should hold securely.

Damage Repair and Component Replacement

One significant advantage of aluminum picket railing systems is component-based design that allows individual part replacement without dismantling the entire system. If a picket is bent from impact with a lawnmower or ladder, that single picket can typically be removed and replaced without affecting adjacent pickets. This modularity keeps repair costs minimal compared to wood railings where damage often requires replacing entire sections.

For scratches or chips in the powder-coat finish, touch-up paint is available from manufacturers in matching colors. While touch-ups won't be invisible, they prevent bare metal exposure and are barely noticeable from normal viewing distances. For more extensive finish damage, individual rail sections or posts can be removed and professionally refinished, though this is rarely necessary during the normal lifespan of the railing.

Post cap replacement is another simple maintenance task. Decorative post caps that develop cracks or fade can be swapped with new caps without disturbing the post or railing structure. Many homeowners upgrade post caps over time, adding integrated LED lighting or changing cap styles to update the appearance of their deck without replacing the entire railing system.

Annual Maintenance Checklist

✓ Clean railing with soap and water (spring and fall)

✓ Inspect and tighten all fasteners

✓ Test gate latches and self-closers

✓ Clear debris from post caps and rail channels

✓ Touch up any powder-coat scratches

✓ Verify post stability and anchoring

✓ Lubricate gate hinges if needed

Cost Analysis and Investment Value

Initial Installation Costs

Professional aluminum picket railing installation typically ranges from $80 to $150 per linear foot installed, depending on system quality, complexity, and regional labor rates. A typical deck railing project covering 100 linear feet would therefore cost $8,000 to $15,000 for complete professional installation. This includes materials, labor, and usually a multi-year warranty on both materials and workmanship.

Several factors influence where a project falls within this range. Simple straight runs with minimal corners and no stairs represent the lower end of pricing. Complex designs with numerous corners, multiple stairs, curved sections, or integrated gates add labor complexity and increase costs. Premium systems with upgraded finishes, decorative elements, or integrated lighting command higher prices but deliver enhanced appearance and functionality.

Material grade significantly impacts pricing. Budget-grade systems from big-box retailers may use thinner aluminum extrusions and lower-quality powder-coating that won't deliver the longevity of professional-grade materials. While attractive for DIY projects where labor costs are eliminated, these systems often disappoint in long-term performance. Professional-grade systems use heavier gauge aluminum, superior powder-coat formulations, and engineered connections that justify the premium through extended lifespan and better appearance retention.

Long-Term Cost Comparison

The true value of aluminum railing becomes apparent when analyzing total cost of ownership over the railing's lifespan. While initial costs exceed wood railing installation, the elimination of maintenance costs results in substantial savings over 10-20 years.

Consider a typical wood railing that requires staining every two years at a material cost of $200 and 16 hours of labor. Over 20 years, this represents $2,000 in materials and 160 hours of